Hydraulic Pumps Repair

Understanding Hydraulic Pumps Repair

When your machinery grinds to a halt because of a hydraulic pump issue, the downtime can feel like an eternity. At Rebellion Calibration and Torque, we've built a reputation on getting you back up and running, armed with quick, quality turnarounds and around-the-clock availability. We're delving into the nitty-gritty of Hydraulic Pumps Repair, a task we're profoundly familiar with, to help you understand the process, the common pitfalls, and how we ensure precision and efficiency in every repair job we tackle.

Common Hydraulic Pumps Issues

Identifying the Culprits

Hydraulic pump failures can lead to significant productivity losses. The usual suspects include contamination, cavitation, overheating, and leakage. Our first step in Hydraulic Pumps Repair is always a thorough diagnosis, pinpointing the root cause to prevent recurrence.

Solving the Puzzle

It's not just about fixing what's broken. It's about unraveling the puzzle of why it broke in the first place. Whether it's contamination that's wreaked havoc on your system or an issue of cavitation leading to inefficiencies, we're on it.

Hydraulic Pumps Repair Process

Time is money, and at Rebellion Calibration and Torque, we're acutely aware of that. Our approach to Hydraulic Pumps Repair is systematic, ensuring not just a swift turnaround but also lasting results.

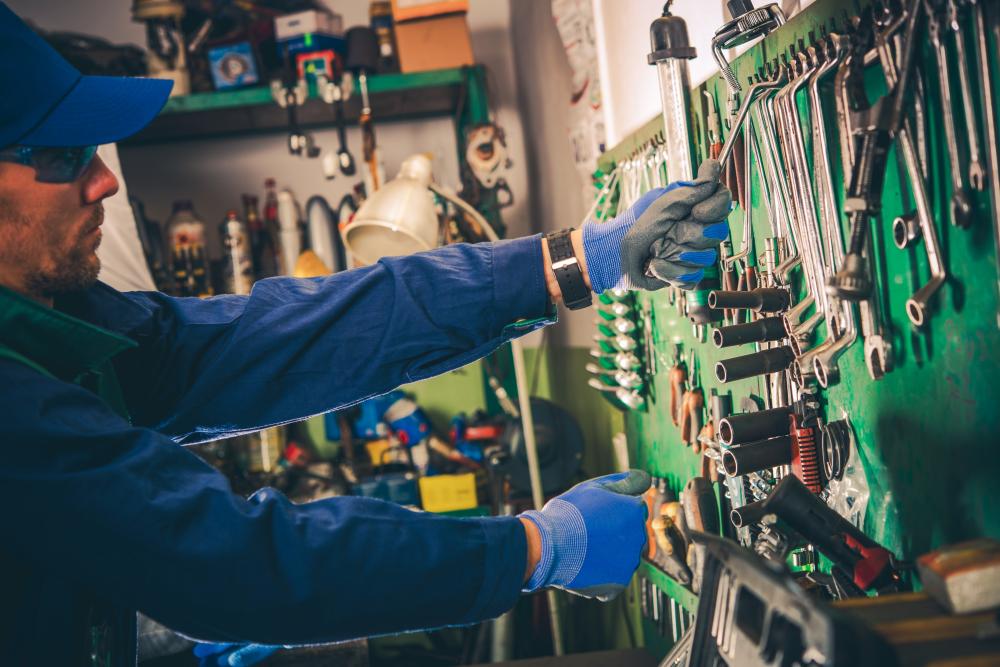

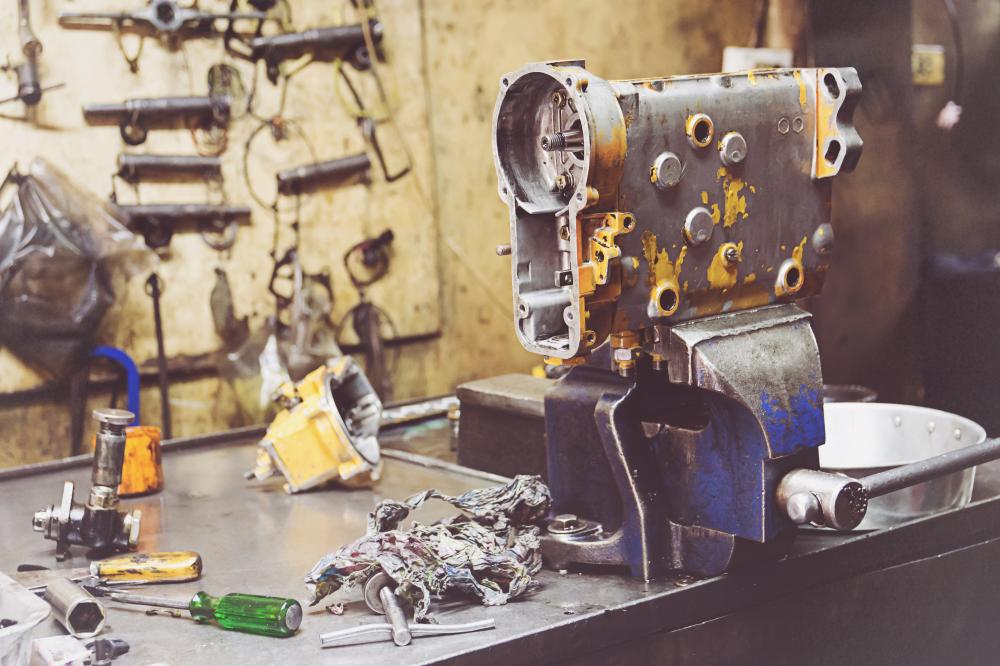

Step-by-Step Precision

From dismantling to cleaning, inspecting, replacing worn parts, and reassembling, our technicians follow a meticulous process. Each step is carried out with precision, employing the best practices honed over years of experience.

Quality Assurance

Post-repair, we conduct rigorous testing to ensure the pump not only runs but runs like new. This commitment to quality underpins every repair job we undertake, embodying our ISO 9001:2015 compliance.

The Rebellion Difference

Experience and Expertise

Our team's extensive experience and expertise in Hydraulic Pumps Repair mean we can tackle even the most challenging repairs. We're not just technicians; we're problem solvers, dedicated to finding the best solution for your needs.

Around-the-Clock Availability

Because breakdowns don't stick to business hours, our services are available 24/7. Whether it's an emergency repair or routine maintenance, our mobile unit can come to you, ensuring minimal downtime for your operations.

Tips for Maintaining Hydraulic Pumps

Regular Checks and Balances

- Monitor system pressure to avoid overexertion of the pump

- Keep hydraulic fluids clean and check for contamination regularly

- Inspect and replace worn parts before they lead to system failure

Adhering to a stringent maintenance schedule can significantly extend the life of your hydraulic pump, saving you both time and money in the long run.

Choosing the Right Repair Partner

Why Rebellion Stands Out

At Rebellion Calibration and Torque, we don't just fix hydraulic pumps; we offer a peace of mind. Our unparalleled service, combined with our precision and efficiency, makes us the go-to partner in Grand Prairie and Northern Alberta for all hydraulic torque wrench needs.

Comprehensive Solutions

Our capability extends beyond repairs. Whether you're looking to rent, purchase, or require calibration services for industrial torque tools, we've got you covered. Our commitment to excellence and customer satisfaction sets us apart in the industry.

Contact Us for Your Hydraulic Needs

Don't let hydraulic pump issues bring your operations to a standstill. With Rebellion Calibration and Torque, you have a partner ready to address your needs promptly and proficiently. Contact us today to learn more about how we can assist with Hydraulic Pumps Repair and more, ensuring your equipment operates at peak efficiency. Remember, when it comes to hydraulic repair, precision is not just a goal; it's a guarantee.

What is the most common cause of hydraulic pump failure?

In my experience at Rebellion Calibration and Torque, the most common culprit behind hydraulic pump failure is contamination. It's something that seems simple but can have complex implications. Tiny particles that aren't visible to the naked eye can wreak havoc on the intricate internal parts of a hydraulic pump, leading to premature wear, inefficiencies, and ultimately, failure. Think of it as the bloodstream of your hydraulic system; just as your body can't function optimally with impurities in your blood, your hydraulic pump can't operate effectively with contaminants in the fluid. Regularly monitoring the cleanliness of your hydraulic fluid can save you a lot of downtime and expenses in the long run. Ever heard the expression "an ounce of prevention is worth a pound of cure"? Well, in hydraulic systems, this couldn't be truer.

How can I tell if my hydraulic pump is bad?

Identifying a problematic hydraulic pump early on can be the key to preventing a full-blown system failure. Common signs include unusual noises, such as knocking or whining, which often indicate cavitation or aeration within the pump. Decreased pressure or flow, leading to sluggish operation or inability to perform under load, is another red flag. Lastly, leaks or visible damage to the pump body are clear indicators something is awry. If you're noticing any of these symptoms, it might be time to give us a call at Rebellion. Just remember, a pump showing signs of wear or failure is like a ticking time bomb for your machinery's productivity and efficiency. Catching issues early can be the difference between a simple repair and a costly replacement.

Why is my hydraulic pump not pumping?

There can be a few reasons why a hydraulic pump isn't pumping as it should. Often, the prime suspects include issues with suction, such as air leaks in the suction line or a clogged filter restricting fluid flow into the pump. It could also be due to the pump being incapable of generating enough suction pressure to draw fluid, sometimes because of internal wear or damage. At Rebellion, we approach this kind of problem with a diagnostic mindset, looking at the hydraulic system holistically. It's akin to detective work, where understanding the relationships between different components is key to unlocking the mystery. Addressing the root cause, rather than just the symptoms, ensures the fix is both effective and enduring.

How do you fix a hydraulic pump cavitation?

Fixing cavitation in a hydraulic pump involves addressing the conditions that lead to its development. Cavitation occurs when the hydraulic fluid is vaporized due to low pressure or high temperature, creating bubbles that implode violently upon entering higher pressure zones within the pump, causing damage to the pump's components. The solution often lies in ensuring the pump is properly primed and that the fluid reservoir is adequately filled. Sometimes, adjusting the system's pressure settings or replacing a clogged filter can also prevent cavitation by ensuring a smooth flow of fluid into the pump. It reminds me of maintaining proper water balance in a swimming pool - it's all about creating the right conditions to prevent problems before they start. Remember, preventing cavitation is far easier and less costly than repairing the damage after it occurs.

What are your top tips for maintaining hydraulic systems?

Maintaining hydraulic systems in top condition boils down to a few key practices. First, ensure you're keeping the hydraulic fluid clean and free of contaminants; it's the lifeblood of your system, after all. Regularly checking and changing filters can help in this regard. Also, monitoring system pressure and temperature can prevent overexertion and overheating. Remember, a well-maintained hydraulic pump is like a well-oiled machine--literally. It runs smoother, lasts longer, and is less likely to give you unexpected downtime. Plus, it's always easier to catch potential issues during routine maintenance than in the middle of a job. Regular checks and balances are your best defense against the unexpected.

How does Rebellion Calibration and Torque offer peace of mind with hydraulic repairs?

At Rebellion, we understand that downtime isn't just inconvenient; it's costly. That's why we've built our reputation on quick, quality turnarounds and around-the-clock availability. Our team of experts combines years of experience with a commitment to precision and efficiency, ensuring that every repair job isn't just done, but done right. Our 24/7 mobile unit means we're available whenever and wherever you need us, minimizing your operation's downtime. With our ISO 9001:2015 compliance, you can be confident in the quality and reliability of our services. Think of us as the emergency room for your hydraulic systems; ready to diagnose, treat, and have you back on your feet--anytime, anywhere.

Why is choosing the right hydraulic repair partner critical to your operations?

Choosing the right hydraulic repair partner is like choosing a surgeon for a critical operation. You want someone with a proven track record of success, who uses the right tools and follows the best practices. With hydraulic systems playing a crucial role in your operations, the stakes are high. The right partner can mean the difference between a quick return to full productivity and extended downtime with mounting costs. At Rebellion Calibration and Torque, we pride ourselves on being that right partner. Our expertise, efficiency, and dedication to customer satisfaction ensure that your hydraulic needs are met with precision and care. After all, in the high-stakes world of hydraulic repairs, trust and reliability are just as important as technical know-how.

Resources

- Hydraulics & Pneumatics: A comprehensive resource for all things hydraulics, offering articles, videos, and guides on hydraulic systems and components.

- Machinery Lubrication: Provides insights and best practices for maintaining hydraulic systems, including information on fluid cleanliness and contamination control.

- Material Handling Network: Offers industry news and resources on hydraulic equipment, maintenance tips, and the latest technologies in the field.

- Filtration + Separation: A source for information on hydraulic fluid filtration and contamination control methods to improve system reliability and performance.

11511 95th Ave

11511 95th Ave